Applications: Avionics Cooling

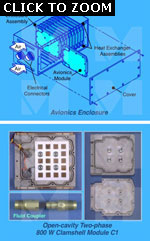

Cooling of avionics onboard modern military and commercial aircraft is achieved inside a rectangular avionics enclosure that serves the multiple purposes of mechanical mounting of circuit boards and electrical interconnect, in addition to the cooling. An avionics enclosure contains several closely packed modules that contain the circuit boards. In the majority of today’s avionics, each module houses two circuit boards mounted back-to-back against a thermally conducting substrate. The substrate routes the heat dissipated by the circuit boards to the top and bottom heat exchange walls of the avionics enclosure, where the heat is rejected to air bled directly from the engine’s compressor or bypassed from the engine’s fan.

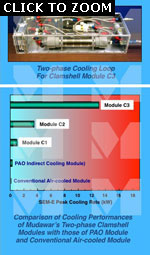

Because of ‘long’ thermal path from device to cooling air, cooling rate of a conventional 5.38 in x 6.41 in x 0.59 in edge air-cooled module is limited to no more than 40 W. However, by the early 1990’s, device and packaging developments in military aircraft resulted in substantial increases in heat dissipation at the module level. Edge air cooling was replaced by a new  generation of indirect liquid cooling modules, where the conducting substrate was replaced by a hollowed, liquid-cooled metallic frame. Using polyalphaolafin (PAO) as single-phase liquid coolant, the heat dissipation capability per module increased to about 200 W.

generation of indirect liquid cooling modules, where the conducting substrate was replaced by a hollowed, liquid-cooled metallic frame. Using polyalphaolafin (PAO) as single-phase liquid coolant, the heat dissipation capability per module increased to about 200 W.

Open cavity Module C1 - Two effective means to improving the cooling performance of an avionics module are to allow the coolant to make direct contact with the device, and to undergo phase change (boiling). Mudawar’s team developed a clamshell-type module, Module C1, which features an open inner cavity inside which two circuit boards are attached to themodule’s inner walls. Dielectric coolant FC-72 is supplied into the cavity and allowed to flow undirected at very low speed before exiting the module to an external conditioning flow loop. They demonstrated that this module could dissipate over 820 W, four times the cooling rate of the PAO module.

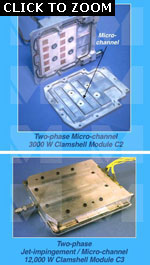

Micro-channel Module C2 - Mudawar’s team later incorporated two-phase micro-channel cooling to further enhance the thermal performance of their earlier clamshell module. The newer Module C2 houses two circuit boards that are separated by a flow distribution plate. The coolant passes through parallel narrow micro-channels formed between the distribution plate and surfaces of the devices. Capitalizing upon the merits of micro-channel flow boiling, Module C2 was demonstrated to dissipate over 3000 W using FC-72, corresponding to a mild flow rate of 0.051 kg/s (0.50 gpm), 40.5°C subcooling, and a pressure drop of only 2.8 kPa (0.41 psi).

Micro-channel Module C2 - Mudawar’s team later incorporated two-phase micro-channel cooling to further enhance the thermal performance of their earlier clamshell module. The newer Module C2 houses two circuit boards that are separated by a flow distribution plate. The coolant passes through parallel narrow micro-channels formed between the distribution plate and surfaces of the devices. Capitalizing upon the merits of micro-channel flow boiling, Module C2 was demonstrated to dissipate over 3000 W using FC-72, corresponding to a mild flow rate of 0.051 kg/s (0.50 gpm), 40.5°C subcooling, and a pressure drop of only 2.8 kPa (0.41 psi).

Jet impingement/micro-channel Module C3 - Another important advancement in two-phaseavionics cooling is Mudawar’s Module C3. This module is double-pitched, meaning it is twice the thickness of Module C1 or Module C2, ensuring electrical and fluid connection compatibility with standard avionics enclosures. Module C3 employs direct jet-impingement of FC-72 upon the device surface, and fluid from the impingement zone is expelled though two micro-channels formed between the flow distribution plate and device surface. Module-C3’s performance exceeded 12 kW, 60 times that of the PAO module. Device heat fluxes as high as 255 W/cm2 were achieved within this module.

Jet impingement/micro-channel Module C3 - Another important advancement in two-phaseavionics cooling is Mudawar’s Module C3. This module is double-pitched, meaning it is twice the thickness of Module C1 or Module C2, ensuring electrical and fluid connection compatibility with standard avionics enclosures. Module C3 employs direct jet-impingement of FC-72 upon the device surface, and fluid from the impingement zone is expelled though two micro-channels formed between the flow distribution plate and device surface. Module-C3’s performance exceeded 12 kW, 60 times that of the PAO module. Device heat fluxes as high as 255 W/cm2 were achieved within this module.

Following are important lessons learned from the development of Mudawar’s three clamshell modules concerning enhancement of avionics cooling:

- Replacing air cooling and indirect liquid cooling with direct-immersion cooling.

- Capitalizing upon the merits of phase change (boiling).

- Enhancing cooling performance through more effective liquid interaction with the surface using such configurations as micro-channel flow and jet impingement.

- Greatly increasing coolant subcooling at the module’s inlet to (i) reduce vapor production within the module, (ii) increase critical heat flux (CHF), and (iii) condense bubbles before they exit the module. Bubble condensation offers the benefits of both simplifying coolant conditioning external to the module, by employing essentially a single-phase liquid loop, and reducing coolant flow sensitivity to large body forces encountered in military aircraft.